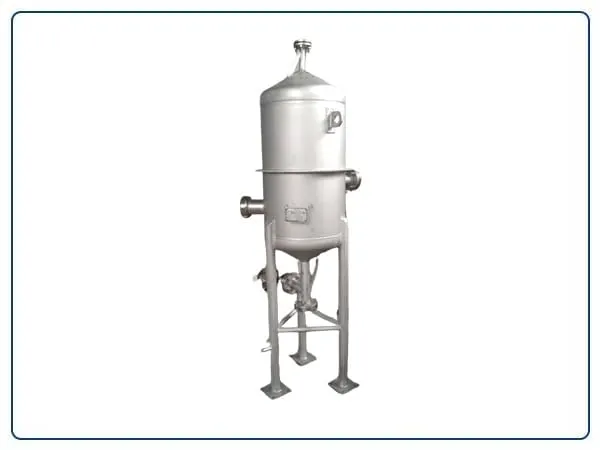

Condenser Manufacturers in Goa and Suppliers in Goa

Upase Process Equipment’s is one of the prominent Condenser Manufacturers, Suppliers, and Exporters in Goa to provide efficient high-performance condensers. Our engineered condensers deliver high-energy efficient heat transfer performance during various thermal industrial processes. Our manufacturing technologies coupled with premium materials allow us to build products that operate effectively under intense pressure and temperature conditions in highly demanding situations. We lead the Condenser Manufacturers in Goa to deliver advanced condensing systems with outstanding thermal performance and long-lasting operational capabilities. Different types of condensers are available through our manufacturing line including air-cooled and water-cooled models which serve particular industry requirements.

Condenser Suppliers in Goa and Exporters in Goa

A condenser represents a heat exchange device that uses heat removal to change vapor into liquid form. The device functions to extract heat during refrigeration operations air conditioning procedures and industrial systems to enhance overall system efficiency. We are the reputable Condenser Suppliersin Goa provide a wide spectrum of condenser products that uniquely fulfill customer requirements. The engineered condensers enhance industrial system efficiency while reducing operational expenses and delivering optimized operational results. We maintain scheduled delivery schedules while providing superior client service to deliver exceptional top-quality products.

We operate as dependable Condenser Exporters in Goa which supplies top-notch condensers to international business customers worldwide. Our dedication to delivering quality performance and satisfying our customers has established us as an industry leader worldwide.

Types of Condenser

The top Condenser Manufacturers in Goa present an extensive range of high-grade Condensers that are flexible enough to be applied in all types as follows:

- Evaporative Condenser: It uses both air cooling and water cooling at the same time. Water falls on the condenser coils and moves across them as air is blown through a fan. The evaporating water takes heat from the system better than traditional water-cooled condensers and saves water during operation.

- Shell and Tube Condenser: A shell and tube condenser contains small metal tubes inside a large hollow chamber. The refrigerant system travels through metal tubes that stay in direct contact with cooling water in the outer shell to exchange temperature.

- Plate Heat Exchanger Condenser: Plate heat exchanger condensers use a series of stacked plates to create lots of heat transfer area. The refrigerant moves through the layered plates and the water coolant moves through the opposite surface.

- Air-Cooled Condenser: Air-cooled condensers transfer heat to the surrounding environment through air. The system contains a heat exchanger with fins while air passes over the tubes through a fan action to chill the refrigerant. These cooling systems work well in systems that need limited water resources.

- Water-Cooled Condenser: On the surface of water-cooled condensers lies water designed to absorb heat from the refrigerant. Water moves through a coil or tube bundle which heats the water that passes through a cooling tower.

Specifications of Condenser

We have added below a technical sheet of our Condenser that provides more technical information such as:

| Specification | Value |

|---|---|

| Type | Air-cooled / Water-cooled |

| Heat Transfer Area | 500–10,000 m² |

| Heat Rejection Capacity | 1 MW – 500 MW |

| Operating Pressure | 2–10 bar |

| Cooling Medium | Water, Air, or a combination |

| Design Temperature | 35°C – 60°C |

| Condensing Temperature | 40°C – 55°C |

| Flow Rate (Cooling Water) | 500–50,000 m³/h |

| Fan Power (for Air-Cooled) | 5–100 kW |

| Shell Diameter | 0.5 m – 5 m |

| Tube Material | Copper, Stainless Steel, Titanium |

| Tube Length | 3–12 meters |

| Number of Passes | 1–3 |

| Fin Density (for Air-Cooled) | 8–14 fins per inch |

| Operating Efficiency | 85–95% |

Benefits of Condenser

Being one of the very best in the category of Condenser Suppliers and Exporters in Goa, all types of Condenser are made using advanced technology and hence offer a variety of benefits such as:

- Environmental Impact Reduction: Through optimized heat transfer condensers achieve two-fold environmental benefits by decreasing industrial waste and detrimental gas emissions during manufacturing operations.

- Improved System Longevity: The utilization of condensers extends equipment duration through compression load reduction which minimizes maintenance needs on cooling components and reduces the need for replacements.

- Versatility: Condensers provide flexible utility because manufacturers adopt them across the air conditioning, refrigeration, and chemical industries thus adapting to multiple operational needs.

- Energy Efficiency: The use of condensers enables the recovery of heat from vapor streams which leads to lower energy bills and better performance levels of cooling systems and refrigeration processes.

- Cost Savings: Operations in HVAC and refrigeration systems and industrial facilities become more affordable through condenser implementations that enhance system function and decrease energy needs.

Applications of Condenser

As Condenser Manufacturers in Goa, our Condenser are highly demanded by multiple types of applications and used for improving performance, such as:

- Distillation Processes: Industrial chemical and pharmaceutical processes depend on condensers to cool their distillation vapors thus enabling the separation of components for achieving pure and proper end-products.

- Automobile Air Conditioning: The A/C system in vehicles incorporates condensers to chill refrigerant as well as condense it and sustain cabin temperature control for passenger comfort.

- Refrigeration Systems: The process of heat exchange run by condensers allows refrigeration systems to release heat from refrigerants thereby achieving low temperatures needed for storage and transport operations.

- Air Conditioning Systems: The effective cooling operation of air conditioners in indoor spaces depends on condensers which release the heat absorbed from refrigerants.

- Power Plants: Power plants utilize condensers to transform steam back into water which improves the energy efficiency and expands the operational range of the thermal cycle.

Upase Process Equipment’s has positioned itself as a primary condenser manufacturers, suppliers, and exporters in Goa. The designed condensers from this manufacturer reach exceptional heat exchange performance for industrial demands. We deliver reliable and effective solutions with a commitment to performance and durability while satisfying specific requirements because of our dedication to excellence which made us a well-trusted name in global condenser markets. Reach out today to get started!