Titanium Pressure Vessel Manufacturers in Chennai and Suppliers in Chennai

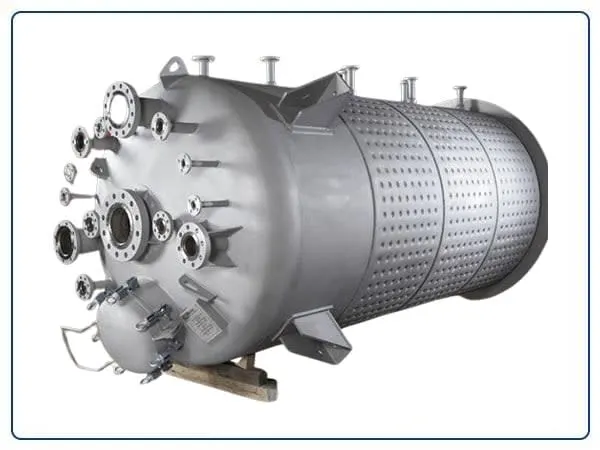

Upase Process Equipment’s foremost provider of Titanium Pressure Vessel Manufacturers, Suppliers, and Exporters in Chennai. The outstanding combination of resilience with corrosion resistance and endurance makes our titanium pressure vessels suitable for industrial sectors which include chemicals as well as pharmaceuticals petrochemical industries. We obligate ourselves to provide dependable and effective pressure vessel products that uphold security standards while delivering peak operational results in tough situations. We operate as the leading trusted Titanium Pressure Vessel Manufacturers in Chennai that specializes in creating sophisticated high-grade titanium alloy pressure vessels. Titanium pressure vessels manufactured handle intense pressure along with diverse temperature conditions making them highly reliable for operation safety. We dedicate our focus to precision manufacturing that results in pressure vessels that fulfill strict global standards while functioning smoothly for critical usage.

Titanium Pressure Vessel Suppliers in Chennai and Exporters in Chennai

The titanium pressure vessel functions as a container that remains stable under high-pressure conditions through its implementation of titanium materials due to its blend of exceptional strength and corrosion resistance and lightness. The high-pressure storage and processing of reactive substances occurs in chemical and aerospace industries together with the oil and gas sector using this material. The Titanium Pressure Vessel Suppliers in Chennai features us as a leader who delivers numerous pressure vessel options in diverse dimensional and technical configurations. We collaborate directly with clients to build personalized solutions that address our operational requirements. We supply pressure vessels according to standard and specialized requirements which provides customers durable performance solutions.

Within our role as top-level Titanium Pressure Vessel Exporters in Chennai we extend our top-quality titanium pressure vessel delivery services to international clients worldwide. We maintain an efficient export network which allows our products to successfully deliver global markets through their high standards of quality and performance.

Types of Titanium Pressure Vessel

As the top Titanium Pressure Vessel Manufacturers in Chennai present an extensive range of high-grade vessels that are flexible enough to be applied in all types as follows:

- Composite Titanium Pressure Vessels: The production of titanium-based vessels involves the fusion of titanium with components made from carbon fiber composite materials to achieve superior strength levels. These vessels operate under high-pressure applications that include aerospace systems together with underwater systems.

- Spherical Titanium Pressure Vessels: The spherical vessel design of these pressure vessels provides exceptional resistance to internal pressure so they have become standard equipment for cryogenic and fuel storage needs. Stress distribution happens evenly because of their spherical form.

- Vertical Titanium Pressure Vessels: Large quantities of fluid flow through vertical pressure vessels before reaching them under extreme pressure conditions. These pressure vessels serve useful purposes in power plants and manufacturing facilities to optimize space utilization.

- Seamless Titanium Pressure Vessels: The materials used to form these vessels consist of one continuous piece of titanium that results in maximum strength and excellent pressure capabilities.

- Welded Titanium Pressure Vessels: The pressure vessels feature a constructed design through shell welding or plate welding to enable versatility in design while allowing larger sizes. Manufacturers use these pressure containers to retain pressurized substances in oil and gas sector operations.

Specifications of Titanium Pressure Vessel

We have added below a technical sheet of our Titanium Pressure Vessel that provides more technical information such as:

| Specification | Value |

|---|---|

| Material | Grade 2 Titanium, Grade 5 Titanium, Ti-6Al-4V ELI |

| Volume | 50 L – 100,000 L |

| Design Pressure | 5 bar – 300 bar |

| Operating Temperature | -200°C – 600°C |

| Wall Thickness | 5 mm – 100 mm |

| Internal Diameter | 100 mm – 5,000 mm |

| External Diameter | 150 mm – 6,000 mm |

| Length | 300 mm – 12,000 mm |

| Corrosion Resistance | Excellent |

| Fatigue Strength | 300 MPa – 900 MPa |

| Heat Transfer Coefficient | 10 – 50 W/m²·K |

| Weight | 5 kg – 5,000 kg |

| Design Code Compliance | ASME, EN 13445, ASME VIII, PD 5500 |

Benefits of Titanium Pressure Vessel

Being one of the very best in the category of Titanium Pressure Vessel Suppliers in Chennai, all types of vessels are made using advanced technology and hence offer a variety of benefits such as:

- High Strength-to-Weight Ratio: The combination of strength and low weight in titanium makes it suitable for pressure-intensive operations while maintaining austere vessel weights.

- Corrosion Resistance: The material withstands corrosion attacks particularly well when exposed to harsh elements including seawater chemicals thus ensuring dependable performance under extreme conditions.

- Excellent Heat Resistance: The material strength of titanium makes it possible to operate effectively at high temperatures while maintaining solid vessel construction during aerospace and chemical processing operations.

- Durability and Longevity: Pressed titanium components made for vessels deliver extended service time because they show resistance to both corrosion and wear which results in lower maintenance costs thereby saving money in the long term.

- Biocompatibility: Because titanium represents a biocompatible material with non-toxic characteristics it establishes itself as an outstanding solution for pressure vessels that will work in medical or pharmaceutical settings.

Applications of Titanium Pressure Vessel

As Titanium Pressure Vessel Manufacturers and Exporters in Chennai, our vessels are highly demanded for multiple types of applications and used for improving performance, such as:

- Aerospace Industry: Spacecraft and aircraft utilize titanium pressure vessels to store fuel alongside hydraulic systems as they incorporate lightweight properties with high strength alongside excellent resistance to extreme conditions.

- Chemical Processing: Processing facilities require titanium pressure vessels to store and transport aggressive chemicals and corrosive substances because the vessels excel at resisting both corrosion and chemical activities.

- Desalination Plants: The corrosion resistance of titanium makes it suitable for seawater desalination pressure vessels where saltwater together with high-pressure conditions do not cause material deterioration.

- Medical Devices: The properties of strength and biocompatibility make titanium pressure vessels suitable for medical applications including oxygen tanks and gas cylinders and some diagnostic instruments which ensure patients receive reliable safe equipment.

- Energy Sector: The properties of extreme toughness allow titanium pressure vessels to serve within energy plants for storing high-pressure gas and hydrogen fuel and managing nuclear reactor operations.

Upase Process equipment’s operates as a Titanium Pressure Vessel Manufacturers, Suppliers, and Exporters in Chennai. These durable and efficient vessels serve industry needs in high-performance environments through our dedication to quality and customer service which made us trusted market standards for unique client solutions. Reach out today to explore our range of durable and efficient vessels designed to meet the highest standards.