Pressure Vessels: Types, Materials, and Advanced Technology

A pressure vessel is a closed-contained design that holds to store gases or liquids at pressures that are higher or lower than the surrounding air. As per the industry requirements we have created our product in premium quality. To get the best pressure vessels in India, it’s important to use standard products equipped with futuristic features.

In this blog, we will explore in detail knowledge about Pressure Vessels their type, features material quality etc. Also, we will learn about new updates and technologies in Pressure vessels.

What Are Pressure Vessels and How Do They Work?

Its main work is to hold different types of gases or liquids. It is required in Industries where high tension and vacuum are required. It is designed to keep workers safe from the internal and external pressure which can break the normal vessel. In Pressure vessels, the liquid and gas stored are mostly at high temperatures.

What are the Different Pressure Vessel Standards?

Different vessel standards are the rules and guidelines that guide you about the safety features, its constructions and operations. These standards are important for preventing accidents of workers.

- ASME Section VIII: The protocols and standards set for the fabrication, inception, design and testing of pressure vessels. To check the safety and reliability in construction of vessels and uses of pressure vessels across industries.

- ASME II: Essential details regarding materials type it uses to make the vessel like steel and welding rod.

- ASME IX: Checks if the workers are well qualified or not and tell how to check welding process and approve it.

These standards should be kept in mind when using pressure vessels.

Pressure Vessels its types and Use:

Pressure vessels vary by its standards of safety, durability and performance. Each vessel is different on its own as per its requirements. These vessels are designed to hold liquid, gas and vapors under high pressure and in extreme situations. Let's see main type of pressure vessel.

- Storage Vessel: These large containers are used to temporarily store liquid, gases or vapors. They are stored to use in process or to ship it as finished product. For example to store compressed natural gas or liquid nitrogen.

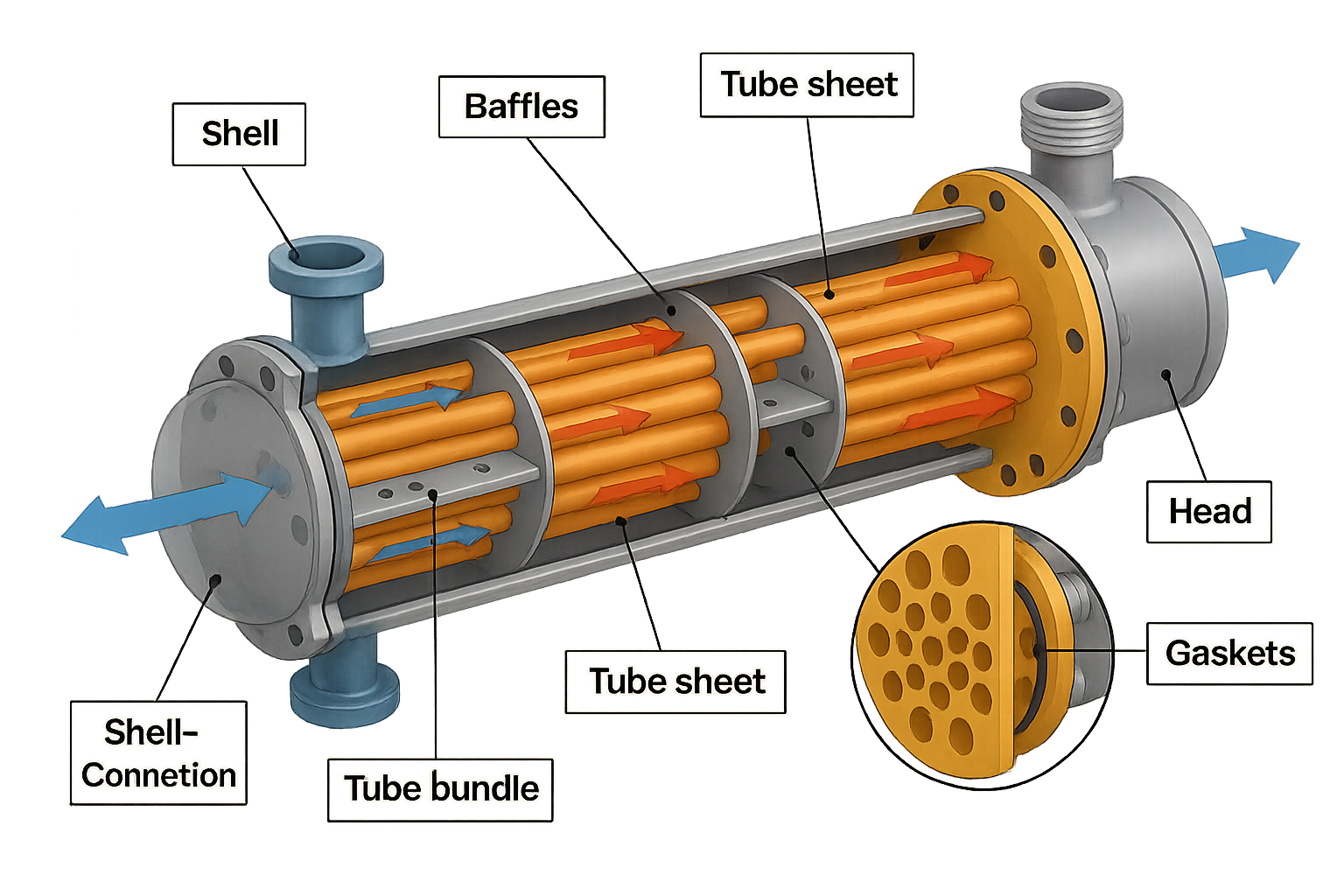

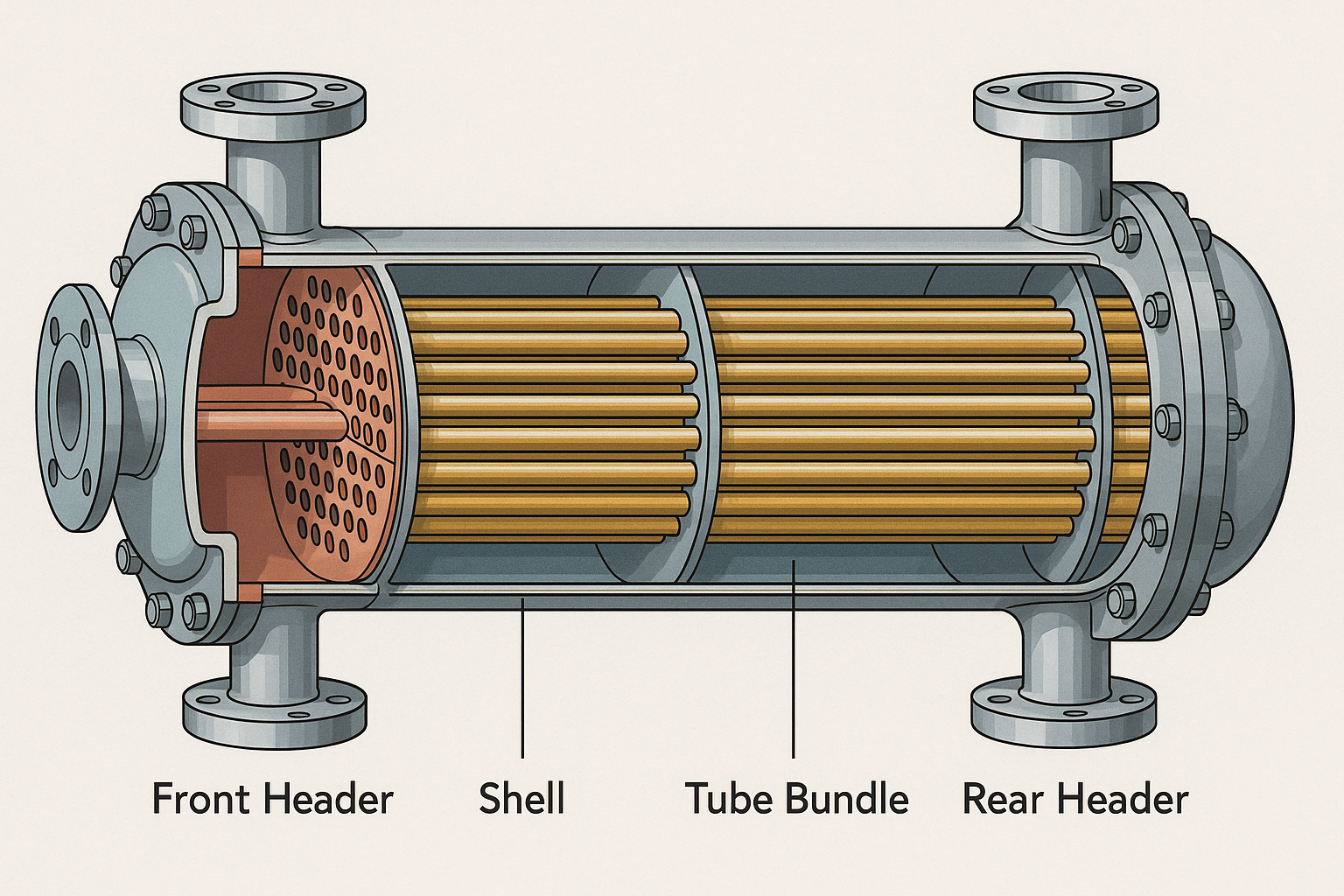

- Heat Exchanger: It transfers heat from one fluid to another without mixing it. It is very common in food and pharmaceutical industries. One fluid flow from the exchanger passing heat from another fluid which is separated by the metal wall. In food industries heat exchanger cool down syrups and heat up the liquid.

- Boilers: These devices are used to transfer heat by using different sources like fuel, electricity, or nuclear power. They are used to handle very high pressure and temperature. Carbon steel, Alloy steel, stainless steel and cast iron are some of the metals used to build boilers.

- Process Vessel: These containers are used in industries to mix, hold, heat or chemically change materials during the manufacturing processes. Food processing, pharmaceuticals and chemical plants use these vessels commonly. It can do a variety of tasks like heat or cool, mix and store. Materials used in it are stainless steel, alloy steel, plastic or fiberglass.

Types of Pressures Vessels according to Geometry:

These vessels are designed according to their geometrical patterns like spheres, cylinders, and cones. Its heads are mostly hemispherical or dished.

- Spherical Pressure Vessel: We provide you with a huge amount of Spherical Pressure Vessel. It is used to store high Pressure fluid because it has a strong structure. There are no weak points in this structure from both inside and outside. But such structures are more expensive than cylindrical vessels. Due to its spherical shape, it absorbs less heat from the surrounding, this makes it better than cylindrical and rectangular shapes vessels.

- Cylindrical Pressure Vessel: We provide you with a large section of cylindrical Pressure vessels. Our vessels are durable cheap and easy to clean and due to this cheaper and easy to clean and because they are easily sold. It works better if you use it for stronger gas- or liquid storage. It is easy to install, strong build and cost-effective.

- Hemispherical Head: We provide you with a Hemispherical Head that is good for handling high-pressure fluid or gases in big containers because they have a simple and round shape which gives you more space inside that's why they are tricky to make. Its curves match its width because they are half as deep as they are wide.

- Conical Pressure Vessels: We provide you with an extensive range of Conical Pressure Vessels to meet the industry's needs. These vessels are built for durability this vessel's conical lower end allows the customer to move powder around their manufacturing plant.

What are the Different Vessel Orientations?

Vessel Orientation differs depending on its available space and its requirements. There are two types of orientations;

- Vertical Pressure Vessels: It is mainly used if there is a lack of space or when there is easy separation of fluid due to gravity.

- Horizontal Pressure Vessels: It is used when size and its stability is more important. They are utilized in large scale liquid tanks.

How to choose materials for pressure vessels and what factors we should consider?

There are several factors that are crucial while selecting the material for vessels. The material must be stronger to handle the extreme temperature. It should be corrosion proof.

- Pressure and Temperature: You can select a vessel that can take the worst-case max pressure and temperature of the process without a failure.

- Material: Choosing a material (e.g. stainless steel or specialty alloys) that will resist corrosion and is appropriate for the fluids or gases inside.

- Size and Volume: Selecting the vessel that can fit in the space you have and has the right amount of volume for your needs.

- Safety and Standards: Choosing your vessel from a well-respected manufacturer that meets safety codes (e.g. ASME) for reliability.

- Maintenance and Cost: Pick a design where inspection and maintenance are straightforward and you achieve a balance of the initial price with long-term price.

Common Materials for Pressure Vessels

Different type of materials is used for Pressure Vessels depending on its requirements. Carbon steel, Stainless Steel, Alloys and Composite materials all are used as per the clients requirements.

- Carbon steel: It is mostly used in low to medium-pressure applications and it is also cost-effective.

- Stainless Steel: Stainless steel cannot corrode easily due to this it is used in making of vessels. It is used in vessels with high Pressure applications.

- Alloys: Alloys are used because it can perform well in higher temper or Pressure.

- Composite Materials: Materials like carbon fibers and fiberglass are used in lightweight vessels.

Future Trends in Pressure Vessel Technology/ Updated Technology:

The Pressure vessel industry has made several updates as per the future needs and requirements. The material in the vessel and its machinery have been through a better change,

- Next Generation Material: We are seeing shifts in materials like carbon fiber and titanium as they are lighter and stronger.

- Digital Twin Tech: Virtual replicas help the engineer’s test how the vessel will perform and what changes are required.

- Hydrogen Ready: This vessel helps to store hydrogen and other clean fuels safely. It is helping to move towards greener energy solutions.

- Modular Reactor Supporter: A smaller nuclear reactor is easily fitted in the vessel. This is helping to produce energy in more places.

Why choose us?

We are a trusted manufacturer of Pressure Vessels in Pune. We are committed to delivering a product that reflects our dedication towards quality and durability. Under the leadership and guidance of our great leader Mr. Vishal Upase and our skilled team of professionals, our company stands out by following the latest trends in the market and by using premium quality materials and advanced technology. We have been in this market, and we have achieved some magnificent goals because each product we deliver undergoes strict quality and durability tests and we work closely with our clients to fulfil their requirements. This is why you should choose Upase Process Equipment where our quality engineering meets future innovations. For more information on high-quality pressure vessels, or to discuss your specific requirements, feel free to contact us today. We’re here to help you choose the right solution for your industry.