Heat Exchanger: Types, Advantages, and Industrial Applications

A Heat Exchanger transfers heat from one medium to another. It is mostly used in engineering, swimming pools, power plants etc. For example, it cools hot oil by using cold water, heats pool water by using hot water from a boiler or solar panels. It works by letting heat pass through materials like metal, without mixing fluids, some of its types use fins and air to do the work while some use tubes.

Heat Exchangers are affordable and environmentally friendly, saves energy which makes them useful in both homes and industries.

Types of Heat Exchangers & its Working

- Plate Heat Exchangers: It is a compact and effective design that helps to transfer heat between two fluids without mixing each other. Thin metal plates create channels and it is mainly made of stainless steel and aluminum. The type of flow it uses is counterflow for easy transfer of heat. It is more compact in size.

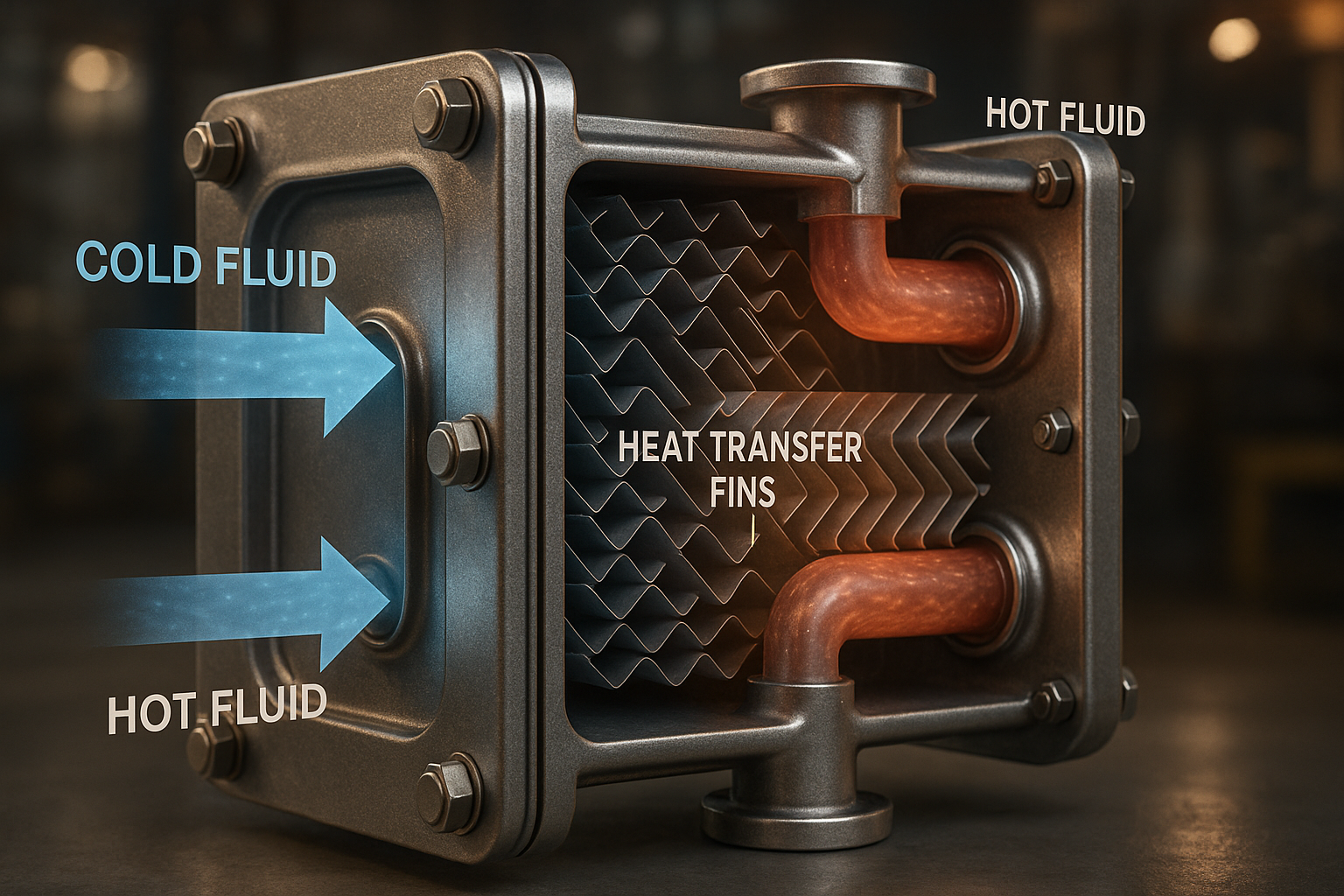

Finned Tube Heat Exchanger: It is mainly made of mild steel, stainless-steel, and aluminum. It transfers heat from the fluid inside the tubes and gas outside. It is mostly used in mining and construction industries. It is easy to maintain.

- Tube Heat Exchanger: It transfers heat between two fluids without mixing them. The heat exchanger consists of tubes from which one fluid flows inside and the other outside. It is mostly made of copper and used in industries like hydraulic and industrial processes. It has conduction heat transfer and a parallel type of flow.

- Double Pipe Heat Exchanger: It is like a tube heat exchanger; it transfers heat without mixing it. It is mostly made of copper but also uses stainless steel and mild steel for manufacturing. Its exchange of heat is through the inner pipe wall via conduction.

- Air Cooled Heat Exchanger: It is mostly made of Stainless steel and mild steel; it cools heat by transferring it to the air. Water is not required in this heat exchanger, which helps to reduce environmental impact. Continuous cleaning is necessary to keep the process better. It is used in power generation, and its flow type is cross flow with convection heat transfer.

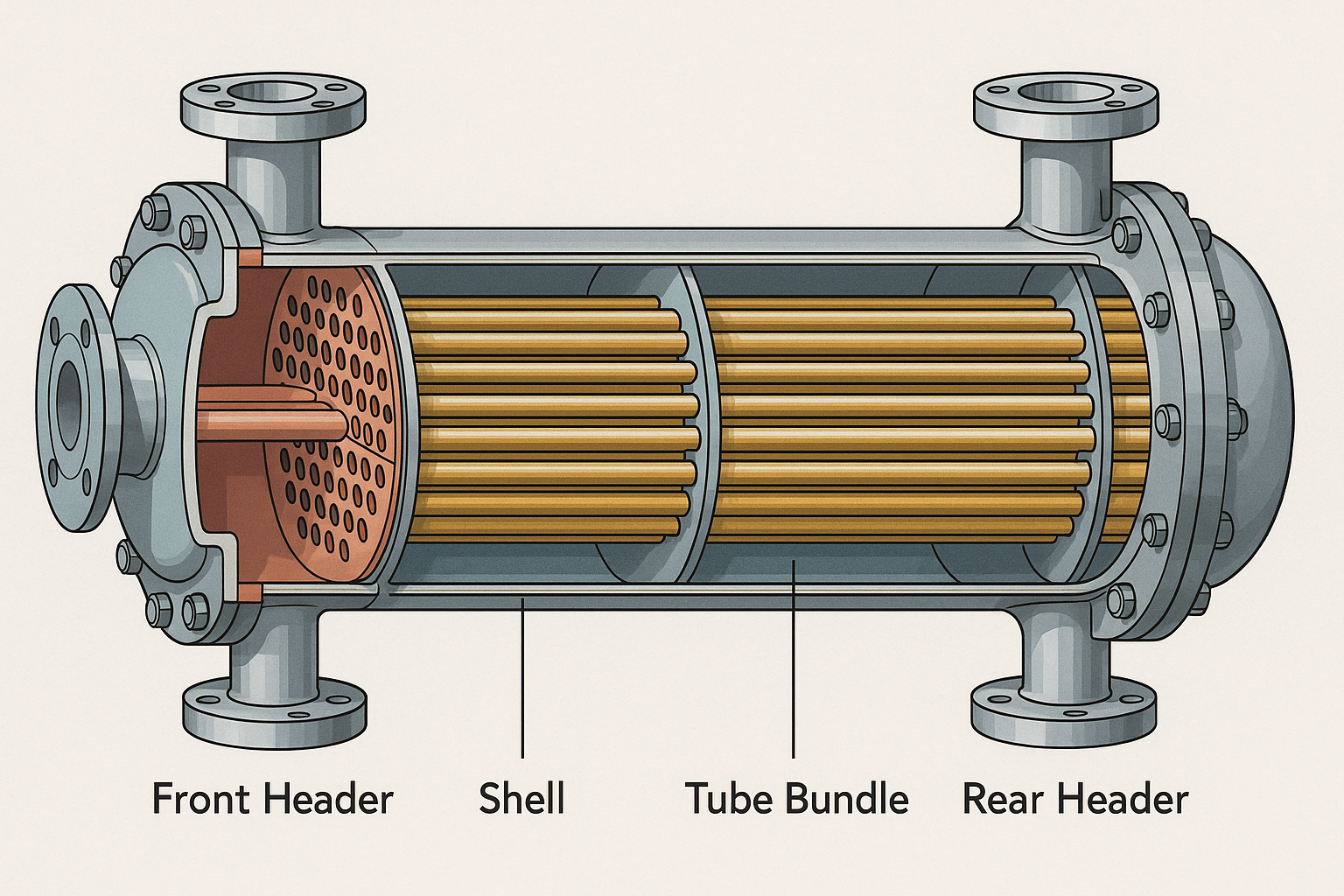

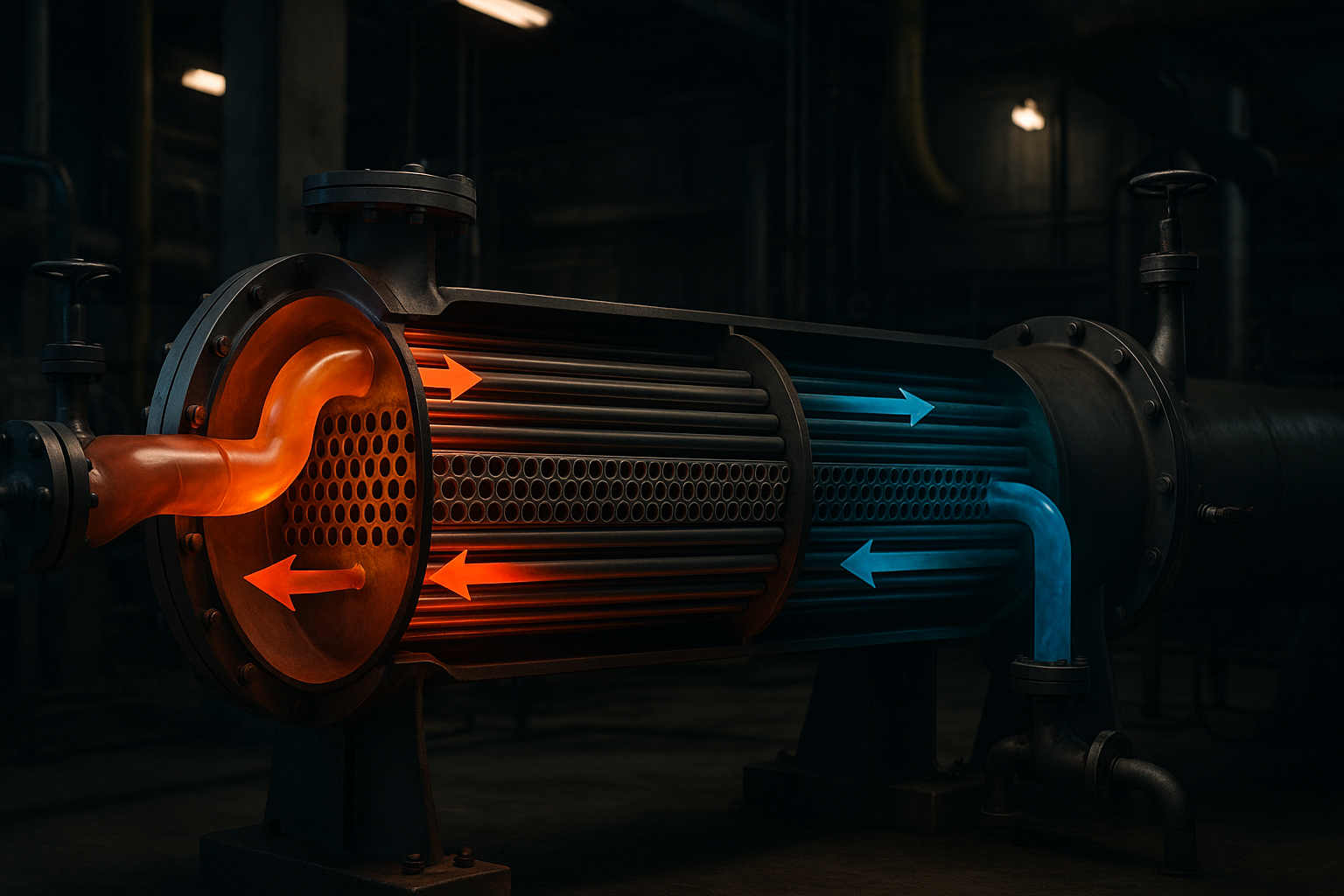

- Shell and Tube Heat Exchanger: It is the top selling heat exchanger. Mostly found in petrochemical plants. It has a bunch of tubes placed inside a big cylindrical shell. Two types of fluids exchange heat effectively, where one fluid flows through the tubes and the other through the surface. It can handle both single and double phases. It has both front and back ends for the entry and exit of fluid. Core components are held by tube bundles, whereas the shell surrounds the exchanger.

Different Types of Flows in Heat Exchangers:

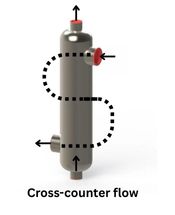

In Heat Exchanger flow is referred to as how the two fluids move inside the device in correlation with each other. These are mostly hot or cold streams, and their movements affect the heat exchanger. There are four types of flow.

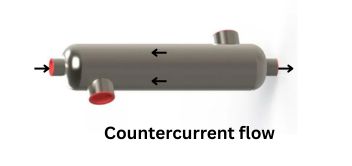

- Counter Current Flow: This flow has the highest efficiency because its fluid temperature difference is larger throughout the exchanger. This type of flow makes the largest change in temperature. Due to this flow, thermal stress is reduced, and it also requires less surface area. This flow is very common in Industries.

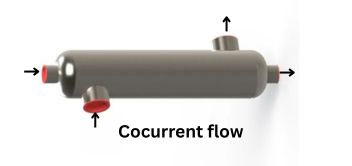

- Co-Current Flow: This flow is also called parallel flow because it flows in the same direction. Its temperature difference decreases as per the length of the exchanger. Due to this, thermal stress becomes higher, and efficiency gets lower in the materials. It’s best used when both fluids need to end at almost the same temperature.

- Crossflow:

It flows at a right angle to each other in the unit. This flow is intermediate compared to the above two flows. It has compact design potential. Due to its flexibility, it is widely applicable. This flow is useful when the space is minimum, or the layout is tricky. It is better than co-current flow. - Hybrid Flow: This flow combines the other types of flows for better performance. This flow is customized by the user to meet requirements. It can transfer heat more efficiently. Most factories and plants use this flow in real-world setups. It can create a good balance in transferring heat easily; it can reduce stress and save space.

Material and Application-Based Classification of Heat Exchangers

| Heat Exchangers | Material | Usage/Application | Flow Type | Heat Transfer Type |

|---|---|---|---|---|

| Shell and Tube Heat Exchanger | Stainless Steel | Pharmaceutical Industry | Counter Flow | Conduction |

| Plate Heat Exchanger | Stainless Steel | Dairy Industry | Counter Flow | Counter Flow |

| Finned Tube Heat Exchanger | Mild Steel | Mining & Construction Industry | Cross Flow | Convection |

| Tube Heat Exchanger | Copper | Hydraulic and Industrial Process | Parallel Flow | Conduction |

| Double Pipe Heat Exchanger | Copper | Hydraulic and Industrial Process | Parallel Flow | Conduction and convection |

| Air Cooled Heat Exchanger | Stainless Steel | Power Generation | Cross Flow | Convection |

Advantages and Disadvantages of Heat Exchangers:

Below are some points which can help you understand better about Heat Exchangers.

Advantages:

- It decreases wastage and saves energy by providing an efficient transfer of heat between fluids.

- This helps in controlling the temperature, which is more important in machines.

- Most heat exchangers have compact designs, due to this it saves you a lot of space.

- By recovering and reusing heat, it reduces energy consumption which helps in saving cost.

- It helps to run the system smoothly by maintaining optimal operating conditions.

Disadvantages:

- Leaks can happen between hot and cold fluids which can contaminate the process.

- Its maintenance, purchases, and installation can be costly, especially the large ones.

- Regular cleaning and maintaining is compulsory for the performance of the machine.

- Most of these heat exchangers have limitations on temperature, and some of them cannot work in extreme temperatures.

- Some designs are very complicated to access, and it takes time to repair.

Why Choose Us?

Selecting Upase Process Equipments for heat exchangers in Pune provides high-quality and innovative solutions for industries in Pune, India. Being a top manufacturer of heat exchangers in Pune. Our heat exchangers are designed with cutting-edge technology and are made from high-quality materials like stainless steel, copper, and titanium. They are designed to ASME and TEMA standards and are energy-efficient for petrochemicals, pharmaceuticals, food processing, and other industries for heat exchangers. With skilled engineers, we produce budget-friendly products for customers. A Customer-centric approach can deliver high-quality heat exchangers modified to your specifications while keeping their pricing budget-friendly customer support. Always trust us for durability and quality heat exchangers.